MULTI-ReUse project is finished

At the center of the MULTI-ReUse project was a pilot plant in Lower Saxony at the municipal wastewater treatment plant in Nordenham. In this coastal region with a lack of water, conventionally treated wastewater was treated further under real conditions, using a modular treatment system in order to be able to use it as process water in industrial companies. MULTI-ReUse has also examined other possible uses that are important worldwide. This includes agricultural irrigation, urban applications and groundwater enrichment. The requirements for this are hygienic safety and the removal of anthropogenic trace substances.

In the pilot plant, the processes of ultrafiltration (UF), reverse osmosis (UO), activated carbon filtration and UV disinfection were flexibly combined into treatment chains. Also, innovative processes for online monitoring of microbiological hygiene and for the determination of biologically usable carbon were developed. When optimizing processes under practical conditions, synergy potential should be exploited by UF and UO in order to make these technologies more attractive for the application in water reuse. An evaluation concept for suitable piping materials was also subject of the study.

In addition to closing procedural knowledge gaps, decision-making aids for potential users were developed in MULTI-ReUse.

Results

The following process water qualities were generated:

• Process water with low requirements, e.g. industrial wash water or water for street cleaning

• Biologically stable process water, with a reduced trace substance content, e.g. for use for irrigation purposes or for groundwater enrichment (elimination of some pharmaceutical substances, benzotriazoles and glyphosate to over 80%)

• Process water with high requirements, since it is low in ions and a minimum of organic trace substances can be generated for certain industrial processes; elimination of almost all examined trace substances, also X-ray contrast media, over 90%

The MULTI-ReUse technology was applied and optimized in a one-year demonstration phase under real conditions. The following process chains/parameters have proven to be suitable for stable long-term operation:

• Flocculation process with iron (III) chloride in the feed to the UF in the so-called coating mode (at the beginning of the filtration time high and then low dosage for a quick iron hydroxide coating on the membrane)

• UF with a flux of 60 L / (m²·h), a yield of 90% and a chemically assisted flush (CEB) every day

• Disinfection by adding 1 mg / l monochloramine (7 hours a day) to the storage tank for UO (reduction of germination and biofilm formation)

• UO with low pressure modules, including innovative spacer with a flux of 16 L / (m²·h), 70% concentrate return and 75% yield

• Chemical membrane cleaning (CIP) of UF and UO as required

• Optional: dosing of powdered activated carbon before the UF to reduce biofouling and RO-common organic micropollutants (benzotriazoles)

The bacteriological online quality control using “flow cytometry” proved to be a very effective monitoring method. It enables the online determination of the total number of cells in the water and its germination potential almost in real time (15 minutes). The strong germination potential of the filtrates and permeates (despite a DOC <0.1 mg / L) determined at the beginning of the pilot tests gave reason to retrofit the disinfection with chloramine for a stable demonstration operation. The integrity of the UF modules can also be monitored using flow cytometry. As a second method, “reverse isotope labeling” was developed, with which the germination potential is determined via the degradability of the DOC in water. In addition, the toxicological effects were checked. No genotoxic potential was found in the water samples along the entire treatment chain. The estrogenic effect determined in the wastewater treatment plant process was reduced by each treatment step and could no longer be detected in the reverse osmosis permeate.

A decision-making aid for the selection of suitable pipe materials for distribution and process water networks was developed and secured by practical studies.

To support potential users of the developed MULTI-ReUse technology, an additional evaluation tool was developed that compares advantages and disadvantages to the current drinking water supply concept for the individual cases. Ecological, economic and social issues are taken into account. A comprehensive assessment for the Nordenham case showed that water reuse enables the supply of higher volumes of water in this region overall at economically competitive prices.

Perspectives for practice

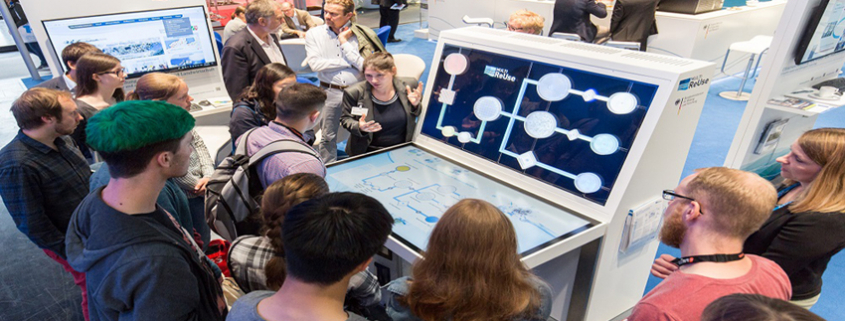

MULTI-ReUse has designed a reference system for water reuse in Germany, which demonstrates process reliability and has a significantly improved quality monitoring. These technologies and the developed Excel-based evaluation tool can be used in Germany as well as in other countries with less water availability. The identification of promising target markets and the development of favourable constellations should also support the transfer of the developed solutions for export. With the help of a MULTI-ReUse short film and a playful, interactive touch table, knowledge transfer on “Learning Expeditions” are also supported. Project results and information on MULTI-ReUse technology and market potential are prepared in factsheets (click here for the factsheets).

This post is also available in: German